FOODTUBES ™

The

transport internet™ – really fast food

Submission for the 2nd round of

The

The main objectives:

1. To design a new local & global eco-transport

infrastructure.

2. To use lightweight

pipeline-capsules to transport food.

3. To reduce incremental CO2

by 18% (1/6th) annually.

4. In the

FOODTUBES can be built and

operated profitably in 100klm sections.

It may be too late to save the ice-caps.

Preventing runaway-global-heating requires major infrastructure

changes.

Foodtubes is invited in

2008 to present commercial transport applications, to:

Transport for

The City of

Capsule-Pipeline Symposium,

Funding:- To date, FOODTUBES

has been financed by the project’s inventor & coordinator, with valued

information and technical support from team members.

The team includes experts

and executives from:

Stoner

Software, ADVANTICA (British Gas); PIAP – Industrial Research Institute for

Automation & Measurement; FUE - Fundacion Universidad-Empresa de Madrid; Clarendon

Laboratories, Oxford; Imperial College London; Warsaw University of Technology; The Freight

Pipeline

21 January 2008.

1. FOODTUBES

– THE TRANSPORT INTERNET - REALLY FAST FOOD.

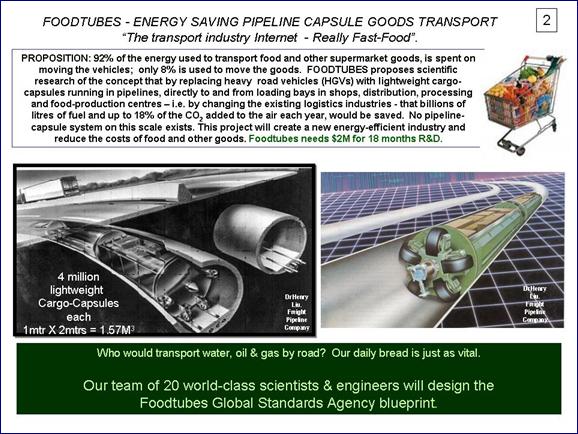

The immediate

objective of the FOODTUBES project team is to design and create global engineering

& IT standards and a business plan for the building and profitable

operation of CO2 saving, lightweight-capsule-pipeline-freight-transport,

suitable for transporting food and other supermarket goods. For example, 1

metre diameter polyethylene underground pipes will be conduits for 2 metre

long, carbon fibre freight-capsules; the

The immediate

objective of the FOODTUBES project team is to design and create global engineering

& IT standards and a business plan for the building and profitable

operation of CO2 saving, lightweight-capsule-pipeline-freight-transport,

suitable for transporting food and other supermarket goods. For example, 1

metre diameter polyethylene underground pipes will be conduits for 2 metre

long, carbon fibre freight-capsules; the

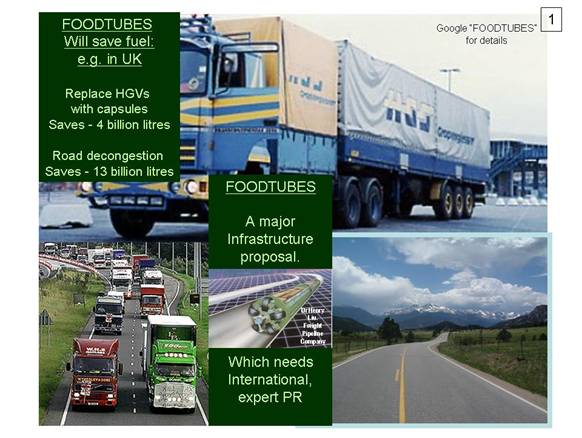

25% of freight

traffic carries food – every day. Which

costs more to move; 300 kilograms of boxed Cornflakes or a 40 tonne, six-axle, tractor,

trailer, fuel tank and lorry driver?

Calculations, Logic

and Outline: http://www.noelhodson.com/index_files/foodtubes9DEC06.xls

Global savings of up to 18% of the annual CO2

increment, and fuel, wages, other savings, and traffic decongestion

improvements could be achieved, with faster deliveries, if the food industry

used a national, and in due course an international, food pipeline system. If

most food-road transport was replaced by food-pipelines, the UK could save

billions of litres of fuel a year, at Ł1 per litre – preserve the countryside,

greatly reduce street-level pollution and global warming gases, and free-up

congested roads.

Summary Targets: http://www.noelhodson.com/index_files/foodtubes_targets.xls

Society continually transports water, fuel, food and people. The

heaviest of these cargos, but the least expensive to transport, is water -

transported in pipelines. Only 8% of the fuel for food transport moves the weight

of the food – 92% is used to move the weight of the vehicles.

Foodtubes will be powered by electrical induction (LIMs), and

pneumatically, with cargos in electronically addressed, high speed (e.g. 100

KPH), lightweight capsules. Like the telephone system, FOODTUBES will have its

own, sustainable, dedicated power-sources. The capsules will be computer

controlled.

The pipeline building costs will be more than recouped through

reduced road building and maintenance. Like water, gas and oil pipes,

food-tubes can be buried for long distances and take shorter routes to

distribution hubs or customers’ “terminals”.

Business-forecasts indicate that Foodtubes will be a highly

profitable system – giving the food industry control over its own regional,

national and international distribution system.

FoodTubes will become the most effective way to move food from region to

region, addressing issues including Food-Miles, Food-Mountains, Bio-Diversity,

Disaster Relief, Farming-Cooperatives, Global-Warming, Street-Level-Pollution

and Global-Free-Trade. Eight global

projects of this scale would start to reverse global-warming.

FOODTUBES has recruited 20 world class engineers, physicists and

executives from various countries to specify the system, to be modelled and

demonstrated by a major, international pipeline owner.

*********

Transport

by road, rail and other modes contributes a large proportion of global warming

gases and other pollution. The current Californian lawsuit against the EPA and

the Bush administration, demanding larger cuts in pollution, cites “vehicles”

as producing 40% of California’s air pollution (Guardian 4 Jan 08). FOODTUBES

sees little merit in replacing diesel with bio-fuels, which create similar

pollutants and, in a hungry world, gobble up productive land or vegetation-carbon-sinks.

The traditional design of vehicles, carrying their own fuel tanks, engines and

drive-trains, lending an illusion of individual independence, needs to change. The

engineering principles are to make MWV’s – Minimum Weight Vehicles – with the

smallest possible vehicle weight/ passenger/ cargo/ ratio, and to power the

MWV’s with sustainable, clean energy – most probably, in the UK with electricity

from tidal power and in California (and Germany) from solar power.

To

transport the volume of all

To

put the proposed

FOODTUBES can start

with short runs of pipes, built and operated under a global standards agency.

It would be feasible for example to link a food centre, like Banbury, to many supermarkets

(“terminals”) via a 150 kilometre pipe.

2.

The FOODTUBES 20 person Team.

See

photographs and CVs at

Project Team: http://www.noelhodson.com/index_files/foodtubes-project-team.htm

We

have scientists and experts from various regions including - North America;

The

FOODTUBES Team needs to be multi-disciplined to tackle the design issues – and

the Team members may change through the course of the project. Their contributions are recognised in Intellectual

Property Rights credits.

3.

The direct and indirect beneficiaries of FOODTUBES

FOODTUBES

will reduce global warming – by stopping up to 18% or 1/6th of the

CO2 added annually to the atmosphere. As such, most of the planet’s

population will benefit.

New

Jobs: The changes are evolutionary. While FOODTUBES heralds reductions in the

journeys of lorries, vans and trains – and a reduction of food-freight drivers

– their jobs will be more than replaced, first by installing the pipeline

systems, and second with permanent jobs for systems managers. There will be a major,

high tech, export, manufacturing industry created to make, lay and maintain

pipes, capsules, monitoring, power and control systems.

Locally,

with short pipeline networks, FOODTUBES will help to clean street level air and

reduce local traffic jams – benefiting the community. Local pipeline operating businesses will be

created.

Regionally,

e.g. across

Nationally,

e.g. in the

Transborder

- e.g. a

Trans-continentally

- e.g. infrastructure in Europe and

Applied

globally, FOODTUBES will achieve the targeted CO2 reductions of 1

billion to 4 billion tonnes per annum – and will greatly improve global

trading.

4.

Original features of the FOODTUBES project.

No

lightweight-capsule-pipeline system exists or is proposed on this scale, for

these applications, with such energy savings.

However,

pipeline-capsule transport dates back 200 years or more. Most modern capsule-pipeline

systems transport ore or coal, in iron capsules, on railways, through pipelines,

propelled by pneumatics. Sumitomo Industries are a large supplier and user of

such systems;

A

small, familiar version is the pneumatic capsules once used in large department

stores to ferry cash and invoices – again being installed in banks etc around

the world.

State of the Art

report: http://www.noelhodson.com/index_files/StateoftheArt-foodtubes2FEB07.htm

When

FOODTUBES files the practical designs, the system may be unique. The initial

models will be computer simulations and the first

5.

FOODTUBES will be offered to and is applicable to all regions around the world.

How

this is being done is described in this text.

6.

The business case is very strong.

FOODTUBES

is analogous to the early days of the railway industry when the manufacturing

countries exported equipment to many parts of the world before the systems were

made locally. At the highly competitive price of, say, US$20 per cargo-capsule

(40 capsules = 1 x 44 tonne truck) and with shorter journeys, convenient

smaller cargos, and fast, secure deliveries – FOODTUBES will replace most other

goods transport. The capital infrastructure and maintenance costs are less than

comparable road, rail and air transport costs. Owning a FOODTUBES operating

system will be very profitable – see the Project-Planning-Tool, where some 3.5

million capsules will be transmitted on most days of the year - US$70 million

per day in revenues + other revenues such as capsule advertising.

Financial “What-If?”

Project Plan: http://www.noelhodson.com/index_files/ftubesfinancials_28Sep07_v15.xls

7.

Success to date.

We

have recruited a world class team including Advantica (British Gas), leading

academic physicists and experienced industry engineers; our Polish partners are

confident of recruiting Gazprom if required. We have agreed the most likely

prpulsion for FOODTUBES. We are invited to propose FOODTUBES as part of the new

London Freight Plan and to make similar representations to the Ministry of

Works, Buenos Aries. We have created a

“What-If?” Project Planning Tool. We

have written a generic application for EC funding. We will present FOODTUBES to

a symposium at the

EC Research

Proposal: http://www.noelhodson.com/index_files/Foodtubes26JUN07PART-B-V12c.pdf

Pipeline Symposium

8.

Applying the US$50,000 prize:

To date, FOODTUBES has been supported solely by its

inventor & coordinator, Noel Hodson, SW2000 Intelligent Transport, with

valued time and expertise from team members. The prize will support the secretariat

in

|

|

|

Contact: Noel Hodson – noel@noelhodson.com Tel 00 44 (0)1865 760994 |

It may be too late to save the ice-caps.

Preventing runaway-global-heating

requires major infrastructure changes.